Last updated:

‘A Jewellery Manufactory in Melbourne: Rosenthal, Aronson & Company’, Provenance: The Journal of Public Record Office Victoria, issue no. 7, 2008.

ISSN 1832-2522. Copyright © Ruth Dwyer.

In the years after the gold rush, as alluvial gold became scarce, many enterprising men in Victoria saw the opportunity to develop secondary industries. One of these businesses was Rosenthal, Aronson & Company, Manufacturing Jewellers of Melbourne. This paper documents the history of the company, from David Rosenthal’s arrival in 1852 until his retirement and the continuation of the firm in 1903 as Aronson & Co. The business closed in 1927, just priorto the Great Depression.

Research for this paper has shown the importance of original documents and contemporary publications when recreating stories of the past. In particular, the Argus newspaper contains regular reports on the activities of the firm and its partners. Its articles on the introduction of tariff protection show how this legislation benefited firms like Rosenthal, Aronson and Co. From its Law Reports it was possible to identify the two criminal cases involving thefts from the manufactory. This then led to a visit to PROV to examine the Criminal Trial Briefs (VPRS 30/P) and to locate the appropriate court transcripts. The second case, The Queen v. Dawes, also contained measured coloured drawings of the interior of the premises. Other documents held by the National Archives of Australia and by PROV helped to fill out the story of a successful business that flourished as part of ‘Marvellous Melbourne’.

Victoria in 1851 – all were off to the goldfields to try their luck![1] As William Howitt observed:

the diggers’ carts are piled with all sorts of diggers’ apparatus – shovels, sieves, cradles, iron buckets, picks, axes, and the like. Behind hang whole heaps of pans, panikins, kettles and iron pots, [and atop], bedding and often two or three women and some children.[2]

Astute men soon realised that to belong to the emerging merchant class offered greater possibilities in all kinds of fields: sly grogging on the diggings, supplying goods to the miners, and manufacturing of all kinds, including of the precious metal. Very soon individual goldsmiths were fashioning presentation pieces of gold, such as the massive ostentatious brooch presented to the notorious Lola Montez in 1855. The more discerning identified a market among the general populace for personal ornaments of a more refined taste. Jewellery manufactories began to appear in subsequent years.

David Rosenthal, a merchant jeweller and a native of Russian Poland, arrived in Melbourne aboard the Sydney in November 1852. His first years in Melbourne were spent in business with other emigrants from Europe, firstly with Hayman Feldheim, then later also Abraham Berens, a relative, as importers and wholesale jewellers at 33 Little Collins-street west until 1859. Rosenthal then continued alone until 1871, when he, with a partner (see below), commenced manufacturing jewellery in Melbourne on his own account.[3] A jewellery manufactory was erected for him in 1872.

The new manufactory, erected for David Rosenthal & Co., Wholesale Jewellers and Importers, at the rear of their then-retail premises at 15 Little Collins-street west, was designed by the architects Messrs Reed and Barnes, prominent in their field in Melbourne.[4] Constructed of stone and brick, it was a substantial building of three storeys, measuring 66 by 20 feet (20.11 by 6.09 metres), and was designed to accommodate fifty-five goldsmiths in comfort. Placement of the windows over the workbenches eliminated danger to their health by ensuring proper ventilation. The charcoal furnaces (which once caused the fire brigade to attend)[5] were on the ground floor. A celebratory banquet was held in honour of the opening of the new building, with the principal, Mr Rosenthal, welcoming some hundred guests.[6]

Gold, in bars and sovereign blanks, was obtained by manufacturing jewellers from the Royal Mint in William Street, Melbourne, these being 91.67% gold; the remainder was of copper. The sovereign blanks were then melted down and other metals added in proportion to give the carat required: 9, 12, 15 or 18. Pure gold – 24 carat – is too soft for such use.[7] The colour of the finished piece was determined by the addition of other metals; for instance, if 25% copper were added to 75% gold the colour would be red-gold. The metal was annealed during the manufacturing process by plunging it into water when black-hot to prevent it becoming brittle. Most locally made pieces were of gold rather than of silver. Although these pieces found a ready market, the wealthier classes still purchased imported jewellery. The Argus reported that

specimens of the colonial goldsmiths’ art have been executed which would do credit to any manufacturer in London or Paris. … in one direction they claim superiority, and that is in connexion with the quality of the material of which their productions are composed.[8]

No doubt influencing David Rosenthal to commence manufacturing jewellery in Melbourne was the decision of the Victorian Government in 1866 to pass legislation introducing tariff protection for local industries. Imported jewellery then carried duty of 10 per cent.[9] David Syme, of the Age, ‘the people’s paper’, championed this cause.

The firm’s beginnings were modest. Included among the thirty men and boys then employed was the manager, Otto Brinkmann, a working jeweller who had emigrated from Hanover, Germany, aboard the Sophia and who had been resident in the colony since 1854.[10] The firm also imported skilled labour, goldsmiths from Germany, possibly including Henry Hessels and Julius Haber. In mid 1871, according to the Argus, manufacturing jewellers were paid between £2 15s and £3 15s per week with the better workmen receiving as much as £5 or £6.[11] The wages paid to apprentices were not listed but would have been from about 2s 6d to 5s per week in the first year. At this time many such tradesmen were unemployed. Output of the factory included ‘brooches, chains, rings, earrings, lockets and studs’.[12]

As early as 1872, the business was described as ‘David Rosenthal & Co., wholesale jewellers and importers, 15 Little Collins-street west’, with no listing for his business partner. The situation was clarified when Rosenthal decided to travel to Europe in January 1875 and was tendered a farewell dinner at Gunsler’s Café prior to sailing. Fellow jeweller and ex-Mayor, Mr Frederick Walsh, occupied the chair and spoke of the Melbourne he had encountered when he first arrived in 1849. Gold had not yet been discovered. It was a city that was neither lighted, paved, nor drained, excepting for Elizabeth-street, a perpetual torrent in which there had been drownings. The streets were bordered by mainly wooden tenements. He hoped that the following years would bring a more prosperous condition than in the past. Walsh then raised his glass to Mr Rosenthal, ‘the beau ideal of a Victorian merchant’.[13] Mr Samuel (sic) Aronson, his partner, was present and responded to the toast.[14] The Aronson family was also Jewish and originally from Russian Central Europe, but had migrated to Bangor, North Wales. Saul Aronson, who was Rosenthal’s brother-in-law, was resident in St Kilda. David Rosenthal, accompanied by his family, travelled aboard the Pera, sailing to Europe by way of Port de Galle, Ceylon, ostensibly calling there to arrange the purchase of gems, in those times an undertaking fraught with difficulty for those without a professional knowledge of precious stones. He remained in Europe during the following year.[15]

Courtesy CGC Gold Pty Ltd.

It was the custom of the business houses of Melbourne to hold an annual picnic for employees and their families, usually during the summer months. In January 1877, the company of some 150 ladies and gentlemen gathered at Mordialloc for a picnic hosted by the resident partner of Rosenthal, Aronson & Company, Mr Saul P Aronson. It is possible that his brother George Aronson was also present as he was in Melbourne at least by 1869. Sporting events took place. Dinner was served followed by the loyal toast, to Queen Victoria, she who was not amused! Then an employee, Mr Lindsay, proposed the health of the firm and wished Mr Saul Aronson well for his return journey to Europe and success in opening a London house. Dancing, perhaps even the risqué waltz, was normally carried on until late in the evening at such functions.[16]

The good wishes for the health of the firm were timely. Although the business was not advertising as a manufactory as yet, developing such an enterprise was not without difficulties. Gold was missing. The lemel box, which was kept in a locked drawer in the office of the manager, Otto Brinkmann, had been pilfered again.[17] Another goldsmith with premises in Little Collins-street, Thomas Young, had been buying gold – sovereign blanks – from a short, scarred, almost toothless balding man of about fifty years of age. As time passed, Young became suspicious and communicated with the Mint authorities. Only three such manufacturing businesses in Melbourne were supplied with sovereign blanks by the Mint. David Rosenthal was informed.[18]

A trap was set. In early January 1877, Brinkmann, in the presence of George Aronson, used a chasing tool[19] to mark two pieces of gold, sovereign blanks. Two weeks later they were gone. The short, scarred, almost toothless balding man, Joseph Ralph, subsequently offered sovereign blanks to Young, who gave him a cheque on the London Chartered Bank for £19 11s 6d for the 5 ounces 9 dwts, then alerted Detectives Hartney and Edleston. They ascertained Ralph’s correct name to be Joseph Ralph Smith and called at his residence at Little Charles-street, Collingwood. Smith was unco-operative. He stated that he had bought the gold from a young man, refused to name or describe him, and claimed not to know where he lived. It became obvious that the young man must have been one of the apprentices in the employ of Rosenthal, Aronson & Company. Smith was escorted to their premises but would not identify any employee. He was charged with receiving stolen property and locked up. A young, slight, fresh-faced apprentice, John Coley, was later arrested.

The case came before the Central Criminal Court in Melbourne on 15 February 1877 before his Honour Mr Justice Fellows. A jury was empanelled. The prisoners stood in the dock. Smith pleaded not guilty. The Sandhurst-born apprentice, John Coley, as he pleaded guilty, had his sentence adjourned to the following day.[20]

PROV, VPRS 515/P0, Central Register of Male Prisoners, Unit 25, p. 205 (detail).

The first witness, George Alfred Aronson, was called.

Detective Hartney came to my office … the boy has confessed. … he cried … he said ‘What will become of me?’. John Coley had taken about 40 pieces of gold from the lemel box, mostly in the late afternoon, and later sold them to Smith. Detective Hartney and I, and the apprentice, John Coley, confronted Smith at Russell Street … ‘Is this the man you sold gold to?’ … ‘You are a damned fool. I would have saved you for the sake of your father and mother and not have put you away.’

Otto Brinkmann testified.

The prisoner, Coley, sometimes assisted me to pack up and put away the gold in the lemel box in the drawer in my office.

Thomas Young took the stand.

I recognize the two pieces of marked gold produced. I got them from prisoner Smith on the 29th of January last. Smith has been selling me gold since 2 November last.

The last witness, Detective John Hartney, gave his testimony, summarising the evidence. Mr Justice Fellows then addressed the jury. The jury subsequently brought down a verdict of guilty.[21]

Smith, a Yorkshire man with a long record in Victoria and possibly in the USA, was sentenced to seven years with hard labour. He again became an inmate of Pentridge Prison. In the ensuing years he committed further offences and died in Pentridge in 1890.[22]

Nineteen-year-old John Coley received two years with hard labour to be served in Pentridge. He did, however, commit one offence therein, being found in possession of tobacco, for which he received three days solitary confinement. Coley was released on 17 September 1878, freedom by remission, with pay of £1 19s 9d. He did not re-offend.[23]

Courtesy CGC Gold Pty Ltd.

In 1878, an auspicious year, the listing for Rosenthal, Aronson & Co. included the words ‘manufacturing jewellers’ for the first time, with George Aronson recorded as a principal of the business as well. Obviously sufficient stock was now available. The annual picnic was a celebration: a cricket match, Mercantile versus Manufactory. With a margin of eight runs, Mercantile won.[24]

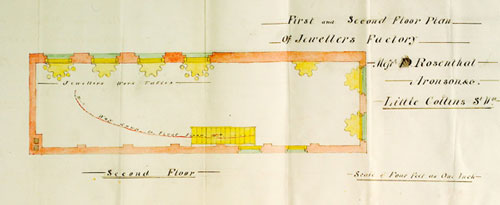

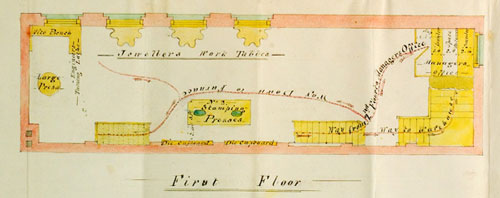

PROV, VPRS 30/P Criminal Trial Briefs, Unit 556, Case number 10 of 5 June 1880, The Queen v. Dawes.

Surviving from 1880 are the measured coloured drawings of the interior of the manufactory.[25] On the second floor of the building were workbenches for thirty-five goldsmiths, with five almost semi-circular, well-lit working positions at each, and suspended leather pouches to catch the lemel. Before him each man had a vertical ‘peg’, a wedge-shaped piece of hardwood to hold the current job in position. A swivelling gas jet was attached to the side of each workbench for the purpose of soldering. Gold for each workman was carefully weighed by the manager, Otto Brinkmann, before manufacture. Then the finished piece of jewellery and any waste was presented to Brinkmann and was again carefully weighed. A very, very small discrepancy was usually noted. Three of the goldsmiths working on this floor were Arthur Dawes, a diamond setter earning £3 a week, Julius Haber, also a mounter of precious gems, and William Wylie. The latter’s work consisted of assembling brooches, soldering the components together, and punching the firm’s trademark thereon.

Unlike in England and many European countries, there was (and still is) no legislation requiring the marking of precious metals in Australia. However, Rosenthal, Aronson & Company chose to do so. The firm’s punch mark, a flag with five stars within, a stylised representation of the Southern Cross, which was struck to either left or right, was most appropriate for a Melbourne manufacturer. It was first recorded as being used in 1880. In earlier years it was simply their initials, ‘R A & Co’, accompanied by a carat mark.[26]

PROV, VPRS 30/P, Unit 556, Case number 10 of 5 June 1880, The Queen v. Dawes.

A stairway led down to the floor below. Where possible in such manufactories it was usual to separate the heavier tools from the goldsmiths’ workbenches. Consequently the stamping press, the large press, the dies, the lathe and the vice bench were all on this floor. Edward Müller, the engineer, worked here operating the presses. Here gold was pressed into form. Dies, female and male, were inserted into the stamping press, with sheet gold between, and the constant swing of the hammer resulted in small gold strikes or stampings to be used as decoration for brooches, lockets, earrings, and so on. Müller also forged tools for use in the manufactory. Henry Hessels was the die sinker and designer. He constructed the steel dies which were stored in shallow cupboards on this floor, and also forged tools such as the mandrels, both large and small. These were tapering round tools used for making such items as studs used to fasten gentlemen’s dress shirts, or rings and bracelets for ladies. Undoubtedly the most important aspect of Hessels’s work for the firm was his designing of the jewellery to be made. He kept his many pattern books on this floor. Owing to lack of space on the floor above, there were three goldsmiths’ benches here, situated on the opposite wall from the die cupboards, again well lit with windows above. August Adamske and Bartholomew Herbstritt, both goldsmiths, worked on this floor. Brinkmann’s manager’s office, where the lemel box was kept, was also here at the head of the staircase leading to the warehouse below.

The warehouse, where retailers called to inspect brooches, lockets, rings and so forth, and then to place orders to purchase, occupied most of the ground floor. A small enclosed area to the west held the two gas furnaces for the purpose of melting metals.[27]

Courtesy CGC Gold Pty Ltd.

The Factories and Shops Act was passed in 1885. Regulations pertaining to premises to be used as manufactories of any description were formulated, and inspectors were employed to examine such premises. Plans had to be submitted to the Local Board of Health showing all floors of the building, a cross-section of same, and drawings of the layout of the yard, if any. If living accommodation were provided on-site, details were required. Means of escape in the event of fire had to be provided, as did adequate space for employees. Some method of heating was required as well as suitable ventilation, lighting and sanitary facilities. Safety measures to be taken when using machinery were to be described. Other measures were later introduced under this Act. Unfortunately these plans of the manufactory of Rosenthal, Aronson & Co. appear not to have survived.[28]

By 1888 as many as 100 hands were employed by the firm, and more than 5000 brooches had been made, in addition to rings, lockets, chains, etc. Having built a prosperous enterprise, David Rosenthal retired in 1889, but still retained a financial interest in the business. Saul Aronson travelled regularly between his London and Melbourne premises, leaving George Aronson in charge of the manufactory in Melbourne. Over time other retail branches were opened in some Australian states.[29]

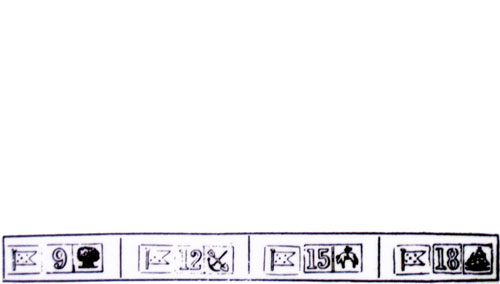

The Manufacturing Jewellers’ Association of Victoria was formed in 1889, the year Rosenthal retired. Two years later George Aronson and other manufacturing jewellers applied for permission as the Manufacturing Jewellers’ Association of Victoria to use carat and guarantee marks. These guarantee marks were a sheaf for 9 carat, a pick & shovel for 12 carat, a fleece for 15 carat and a three-masted ship for 18 carat in respect of goods of precious metals. It is unclear exactly when this marking system began to be used; illustrations of it first appeared in the first issue of the Australian Manufacturing Jewellers’, Watchmakers’ and Opticians’ Gazette in 1906, but agitation for such a marking system had begun before 1885.[30]

Courtesy CGC Gold Pty Ltd.

New and extensive brick premises designed by Nahum Barnet were erected for Rosenthal, Aronson & Company in 1892 at 275-281 Lonsdale Street, near the intersection with Swanston Street. The application to move the manufactory to the rear of this site was lodged with Melbourne City Council in April of that year for the approval of the Chief Inspector, Harrison Ord, appointed under the Factories and Shops Act. Iron fire-proof construction was used and Grinnell’s sprinklers were installed, also insulation and hydrants. A system of elevated wash stands with receptacles beneath was fitted to catch the small gold particles from the employees’ hands, and it was estimated that this would save up to £50 worth of gold annually. The Factories and Shops Act now required a continual stream of air to circulate throughout the building (though much to the ire of the inspector, most manufactory workers pasted paper across these apertures during the colder months). Mechanical power, a gas engine of four horsepower, was installed. Fewer manufacturing jewellers were to be employed owing to the now unwelcome effects of the protective system and Victoria’s precarious financial state. Although the customs duty payable on imported jewellery was now 20 per cent, some retailers were bringing in unfinished goods which only required a bare minimum to finish the pieces, thereby avoiding the duty. The manufacturers asked for 50 per cent, however the amended tariff passed was 25 per cent – and this now included unfinished goods. During these years, Rosenthal, Aronson & Company employed only twenty-eight men and boys and five females. The latter were paid a lesser amount per week, a minimum of 30s for a 48-hour week, while some males were awarded as much as 60s. This was considerably less than the wages of up to £6 received in 1871.[31]

In 1900 the Victorian Government passed legislation enabling the appointment of a Jewellers’ Board under the Factories and Shops Act. This board was constituted to set wages for employees and regulations governing apprenticeships. It consisted of a chairman and equal representation of employers and employees, the maximum being five of each. Elections were held to appoint members. Rosenthal, Aronson & Company were not represented as employers. The reason may have been the departure in 1900 of George Aronson, who returned to England.[32] It is not known if one of their goldsmiths was a representative of the employees. Also in this year, under this Act, Henry Newman, the grand old man of the trade, a retailer and manufacturer, began collecting signatures for a petition in support of a half holiday. Support for closing at 1.00 pm on either Wednesday or Saturday afternoons was evident. In the City of Melbourne a half holiday was granted.[33]

On 30 July 1901, Rosenthal, Aronson & Company sought approval from the inspector at the local municipality, Melbourne City Council, to move back to Little Collins-street at no. 297 near Royal Arcade. The building was of brick with a slate roof. Employed were to be one man in the smelting room, two engineers, and fifty-nine goldsmiths, including three females, who were usually employed in finishing and polishing pieces. The goldsmiths, or manufacturing jewellers, were to occupy premises measuring 144 by 24 feet (43.89 by 7.31 metres), with a height of 13 feet (3.96 metres). The twenty-four windows were double hung to allow adequate light and ventilation. Sanitary conditions were satisfactory. Double doors opened outwards to allow for easy escape in case of fire. Mechanical power was supplied by an electric engine of five horsepower. The Jewellers Board determined that 50s per week be paid to mounters, setters, ring makers and chain makers etc., and 60s to chasers and engravers. Apprentices in their first year received 5s a week rising to 40s in the last and seventh year. The wages of their travellers, such as John Harris Marks and Mr Holtz in Wagga Wagga (where the town was plastered with bills offering £50 reward for the recovery of his supposedly stolen goods),[34] are unknown. They may have been paid on a commission basis.[35]

Also in 1901, in October, the business still known as Rosenthal, Aronson & Company was floated as a public company, with £90 000 in shares of £100 each. It is unclear whether David Rosenthal still had a financial interest in the business at this time. After making his will in 1893 he lost all his money during the Depression of the 1890s, though he was able to compromise with his creditors, thereby avoiding insolvency. At his death, his personal estate was valued at £177 2s 7d. He owned no real estate. (It was a common practice for men involved in their own enterprises to put the family home in the name of their spouse after the passing of the Married Women’s Property Act in 1870.) The Lonsdale Street building had been sold prior to Rosenthal’s death, presumably in part to provide for this impecunious manufacturing jeweller and his family.[36]

In 1903 the business became Aronson & Company as David Rosenthal was no longer a partner. He passed away on 7 March 1910 aged 84 at his residence, Amoe, in Redan Street, St Kilda.[37] He had lived in Melbourne for over fifty years, and for almost forty years had been engaged in manufacturing jewellery. It was unfortunate that he was unable to benefit from what continued into the early twentieth century to be a very successful enterprise. The manufactory was sold in 1927.[38] It is still possible today to find examples of the jewellery of Rosenthal, Aronson & Company, carrying their punch mark – a flag with five stars within.

Appendix: Principals and Employees at Rosenthal, Aronson & Company, Melbourne

The following principals and a number of employees of Rosenthal, Aronson & Company in Melbourne are listed below. Some employees may have continued when the business became Aronson & Company in 1903. The spelling is as found.

David Rosenthal (b. Russian Poland c. 1825, d. Melbourne 1910), Saul Philip Aronson (b. Bangor, Wales, c. 1845, d. London 1931), George Alfred Aronson (b. Bangor, Wales, c. 1848, d. London 1910).

Nuriel Aronson (Norman), Thomas J Flynn, WA Walton, John D Rosenthal, Ernest Hogarth, Snr & Jnr, J Hansen, R Wolffe, F Brienkman (Otto Brinkmann, manager), Charles Wigg, Peter Scherwager, F Haber, J Johnstone, H Beyer, Henry Lange, F Tilley, Alf Stokes, F Parrish, William Parrish, Percy Wadleton, T Dennison, H Petersen, G Alexander and his son, C Jenkins, Fred Stannus, George Stott, Walter Walton, John Harris Marks (traveller), John Coley, William Wylie, Henry Hessels, Edward Müller, Bartholomew Herbstritt, Julius Haber, Arthur Dawes, August Adamske, Mr Holtz (traveller), Mr J Lindsay, Thomas Morton, Gustav Paul Schober (known as George).

Endnotes

[1] I am grateful to Andrew J Walsh, of Robt H Parker and Sons Pty Ltd, manufacturing jewellers since 1875, for his reading of the text and assistance in dating pieces. I also thank Professor GWK Cavill for his reading of the text and permission to use the images of the jewellery of Rosenthal, Aronson and Co.

[2] W Howitt, Land, labour & gold, or two years in Victoria with visits to Sydney and Van Diemen’s Land (1855), Lowden Publishing Company, Kilmore, Victoria, 1972, p. 63.

[3] National Archives of Australia (NAA), A712/1 1855/12259, Applications for Naturalisation, David Rosenthal; Sands & Kenny’s commercial and general Melbourne directory for 1859; Argus, 17 December 1859, p. 3e. The history of Rosenthal’s partnerships and addresses can be followed in the annual Sands & Kenny (later Sands & McDougall) directories.

[4] Joseph Reed and Frederick Barnes, architects, also designed the Trades Hall, the Exhibition Building, the Collins Street Independent Church and other notable buildings.

[5] Argus, 9 February 1877, p. 5d. No Fire Inquest was located in PROV, VA 862 Office of the Registrar-General and the Office of Titles, VPRS 407/P0 Fire Inquest Deposition Files.

[6] Age, 25 November 1872, p. 2f; Argus, 25 November 1872, p. 5b.

[7] 9-carat gold = 0.3750 parts of 1,000 (or 37.5 per cent), 15-carat = 0.6350 parts of 1,000 (or 63.5 per cent), and so on. Gold melts at 1054o centigrade.

[8] ibid.

[9] GD Patterson, The tariff in the Australian colonies 1856-1900, FW Cheshire, Melbourne, 1968, pp. 20, 48. The firm had always imported glassware, jewellery, crockery, electroplated ware, optical goods and so on.

[10] NAA, A712/1, 1857/1583, Applications for Naturalisation, Otto Carl Heinrich Brinkmann. I suggest that the correct order of his name was Carl Heinrich Otto Brinkmann, as usually the German-born immigrants were known by their last given name.

[11] Argus, 12 August 1871, Supplement, p. 2g.

[12] Argus, 25 November 1872, p. 5b.

[13] Argus, 27 January 1875, p. 5b.

[14] Age, 27 January 1875, p. 3a.

[15] PROV, VA 606 Department of Trade and Customs, VPRS 3506 Outwards Passengers to Interstate, UK and Foreign Ports (Microfilm Copy of VPRS 948), Reel 43, Rosenthal. Ceylon is now Sri Lanka.

[16] Argus, 22 January 1877, p. 5e.

[17] Lemel is the trade name for the gold and silver filings which collect in pouches suspended from goldsmiths’ workbenches. These, and the ‘sweeps’, a mixture of dust, debris and metal from the floor, are sent to be refined.

[18] The case was reported in the Argus, 1 February 1877, pp. 5c-d and 2 February 1877, p. 5c.

[19] Steel chasing tools of various sizes with rounded ends are used with a small hammer to move metal on the front of a piece to create a design.

[20] In 1877, those accused were not permitted to give evidence on their own behalf, or to be cross-examined. Sandhurst was re-named Bendigo in 1891.

[21] PROV, VA 667 Office of the Victorian Government Solicitor, VPRS 30/P Criminal Trial Briefs, Unit 501, 5/2/77 The Queen v. Smith and Coley; Argus, 16 February 1877, p. 6f ‘Stealing Gold’.

[22] PROV, VA 1464 Penal and Gaols Branch, Chief Secretary’s Department, VPRS 515/P, Central Register of Male Prisoners, Unit 25, p. 205, Smith; PROV, VA 863 His Majesty’s Gaol, Pentridge, VPRS 10858/P Registers of Personal Descriptions of Prisoners Received, Unit 1, p. 479, No. 07932, previously No. 14458, Smith.

[23] PROV, VPRS 515/P, Unit 25, p. 206, Coley; PROV, VPRS 10858/P, Unit 1, p. 486, No. 14459, Coley.

[24] Argus, 8 February 1878, p. 5g.

[25] PROV, VPRS 30/P, Unit 556, Case number 10 of 5 June 1880, The Queen v. Dawes, including measured coloured drawings of the interior of the manufactory of Rosenthal, Aronson & Co. GE Gee, The practical gold-worker, Crosby Lockwood, London, 1877, pp. 80-91; GE Gee, The goldsmith’s handbook, Crosby Lockwood and Son, London, 1881, revised edition 1922.

[26] K Cavill, G Cocks & and J Grace, Australian jewellers: gold & silversmiths, makers & marks, CGC Gold Pty Ltd, Roseville, New South Wales, 1992, p. 32.

[27] For a general discussion of jewellery manufacture at this time see Argus, 23 February 1885, p. 7a-c ‘The industries of the colony. No. V. Jewellery’.

[28] Victorian Government gazette, Supplement, 24 December 1885, p. 295 and 13 June 1890, p. 2453. Details concerning living accommodation on-site were especially aimed toward the Chinese, mainly cabinet makers, but also at a small number of manufacturing jewellers who worked in sub-standard conditions, usually in their dwellings.

[29] A Sutherland, Victoria and its metropolis, past and present, 2 vols, McCarron, Bird & Co., Melbourne, 1888, vol. 2, p. 574.

[30] NAA, A11731, 2607-2610, Applications for Registration of Victorian Trademarks; Argus, 23 February 1885, p. 7.

[31] Argus, 29 July 1892, p. 5e ‘The Revised Tariff’; PROV, VA 511 Melbourne City, VPRS 3181/P0 Town Clerk’s Files, Series 1, Unit 250, 1892, Factories and Shops, Inspector’s Report, Rosenthal, Aronson & Co.

[32] Argus, 6 December 1900, p. 5a.

[33] Victorian Government gazette, 16 November 1900, p. 4279; 25 January 1901, p. 291; PROV, VPRS 3181/P0, Unit 268, 1901/3239 Jewellers’ Petition for a half holiday. The Jewellers’ Board was also known colloquially as the Wages Board.

[34] John Harris Marks was the son of Charles Marks, jeweller, of Ballarat. Holtz was robbed of stock worth £300 in Wagga Wagga in that year; it was recovered (Age, 15 July 1881, p. 3a; 16 July 1881, p. 5g).

[35] PROV, VPRS 3181/P0, Unit 268, 1901/3083 Factories and Shops, Inspector’s Report, Rosenthal, Aronson & Co.; Victorian Government gazette, 19 July 1901, p. 2752; State Library of Victoria, MS 11756, Box 1875/14; Australian storekeepers’ journal, 26 October 1901, p. 285.

[36] PROV, VA 2620 Registrar of Probates, Supreme Court, VPRS 7591/P2, Unit 447, File 115/828, will of David Rosenthal; PROV, VA 2624 Master in Equity, Supreme Court, VPRS 28/P3, Unit 129, File 115/828, probate and administration of David Rosenthal; PROV, VA 3022 Castlemaine Courts, VPRS 12873/P1 Index to Insolvencies (1871-1911), List of Certificates Granted and Issued (1875-1900), David Rosenthal.

[37] Index to Deaths in Victoria, 1910, no. 3520.

[38] According to the Australian manufacturing jewellers’, watchmakers’ and opticians’ gazette of 2 March 1931, p. 5, Aronson & Company continued manufacturing jewellery until August 1927 when their factory and plant were purchased by WH Dempsey and Company Pty Ltd, manufacturing jewelers.

Material in the Public Record Office Victoria archival collection contains words and descriptions that reflect attitudes and government policies at different times which may be insensitive and upsetting

Aboriginal and Torres Strait Islander Peoples should be aware the collection and website may contain images, voices and names of deceased persons.

PROV provides advice to researchers wishing to access, publish or re-use records about Aboriginal Peoples